“Keep, Change, Create” ™

We create strategies for both private and public sectors;

to provide Proven Process based interventions to

embed Enterprise Wide Strategic Change

AOQ WEBINAR

Solve Smarter, Not Harder with ISO 10009 2024 Quality Tools and Storyboarding for linking Problem Solving with Prevention

Tired of recurring problems? Learn how to apply the new ISO 10009:2024 Quality tools and storyboarding to solve root causes, reduce variation, and deliver lasting results in your processes and management systems.

Michael McLean (Juran Medallist and ISO Expert) will provide participants with a comprehensive introduction to structured problem-solving approaches grounded in international standards and continual improvement frameworks.

During the 60-minute session, attendees will explore how Dr W. Edwards Deming’s PDSA (Plan-Do-Study-Act) Learning Cycle forms the foundation for learning effective problem solving and problem preventative strategies including Process Failure Modes and Effects Analysis (FMEA). Learn how to distinguish between an event and a process-generated problem. Snippets from various industries to gain an understanding of effective application of quality tools from ISO 10009:2024. A key feature will be the practical use of ISO 10009 Annex A storyboarding, to demonstrate how structured problem-solving aligns with strategic business planning, Lean Six Sigma™, and continual improvement.

The session will build participants’ knowledge of several internationally recognised problem-solving methods, including PDCA, DMAIC, A3, and 8D, while emphasising the importance of precise problem definition through the MMC “F.O.E.” approach. Core concepts from leading quality thinkers such as Ishikawa, Taguchi, Deming, Juran, Imai and Wheeler will be discussed to show how organisations can effectively improve true root cause analysis and reduced process variation.

The Australian case studies will be shared from wholesaling, biomedical, and service/insurance sectors will illustrate how the Quality tools can be applied in different contexts, reinforcing the idea that a high number of recurring problems often signals ineffective FMEA application. The webinar will conclude with information on further learning opportunities, post-session resources, and support available through consultancy or coaching services.

Wednesday 30th July 2025

Online (MS Teams)

6pm – 7pm (AEST – Syd/Melb/Bris time)

$10 members; $40 for non members

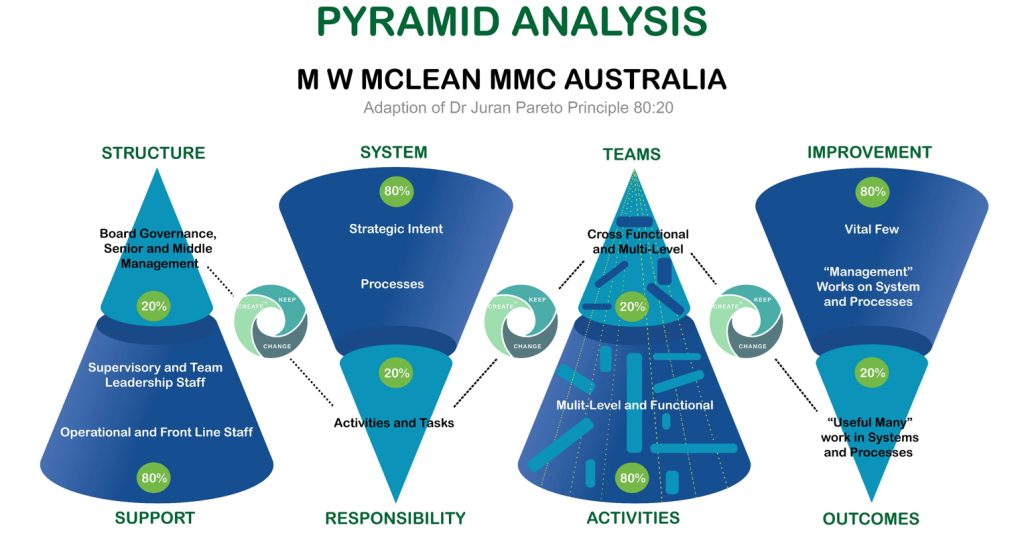

THE MMC Approach - Pyramid Analysis

Our management consultants, associate consultants, advisers, and coaches deliver agreed client outcomes under the ISO 20700:2017 Management Consulting Services – Guidelines.

Using the Keep, Change, Create ™ methodology with our “Pyramid Analysis” shown, was developed in 1988 based upon MMC assignments in Asciano, BHP, Boral, Changi Airport Singapore, CSR, Coal & Allied, Graphic Packaging International, RAAF, RAN, Suncorp, Surveyor Indonesia, Westpac and Zurich Insurance.

It provides the basis for MMC clients to assess where and who is accountable and responsible for making organisation, structural, cultural, process, products and services, and perhaps supply chain changes.

Embedding Strategic Change Methodology

Our “Keep, Change, Create” ™ approach to Embedding Strategic Change and is used in Strategic Planning workshops as summarised for 2 not for profits as shown conducted in 2024.

- Optimizing stakeholder needs to achieve strategic goals, risks and opportunities

- Business Acumen and risk-based thinking leadership practices in processes

- Integrating business management requirements into business processes

- Aligning continual improvement projects to business strategies and processes

- Sustaining systemic risk management guidelines and principles in business processes

MMC Client Outcomes

- One of Australia’s largest Building and Construction materials ASX Listed companies:

– 17% ROI for Breakthrough CAPEX Projects

– 414% ROI for Incremental OPEX Projects - Reduced Average Projects time from 120 to 24 weeks and secured a State Government Animal Research Agency contract

- Increased Australia’s largest complex project and export business from 650 to 1750 units per day and Right First Time from 85% to 99%

- Indirect productivity of 26% and 41% in Australia and Internationally in Banking, Manufacturing, Insurance and Smelting

- 10-person manufacturer monthly output and revenue growth from $220,000 to $375,000

- 50% reduction in factory and warehouse layout with a 25% increase in output to secure a long-term Oil and Gas Contract)

- Micro-business clients (3-persons) a Distributor and Defence/Transport doubled sales since achieving ISO 9001:2015 Accredited Quality Management System Certification with 2 years.

- ISO 9001 Re-certifications for:

– Defence CASG: Air Lift SPO, Battlefield Communications SPO, Information Assurance SPO

– Sucofindo Indonesia, General Motors Indonesia, Reliance Hexham, Specfast, TW Woods - Integrated Management System certification and re-certifications:

– Power Projects International, Global Rotomoulding, Graphic Packaging International (Fortune 500 Coy operating in NSW and Victoria; James Walker Australia; Jemena

MMC Problem Solving Pocket Guide (PSPG)

- Have your “Breakthrough” (Dr J Juran) Projects achieve a 14% ROI and “Kaizen” Projects achieved 414%+ ROI?

- The first edition was in 1996 and was truly ‘pocket-size’ and again in 2000, to support clients’ Continual Improvement programs and projects such as the Asciano, Royal Australian Air Force, Boral, CBA, CSR, Royal Australian Navy, General Motors, and Suncorp Insurance.

- The MMC Problem Solving Guidebook (PSGB) and the 28 Tools and Techniques for Continual Improvement that was sold in Australia and Internationally through Bywater (ASEAN, Middle East, USA USA).

- The 2024 MMC PSPG has been revised and resized to A4 as it provides additional Guidance

- It has drawn from MMC clients and different problem-solving methodologies that suit their Context and Corrective Action procedures within their ISO Management System Accredited Certifications.

- The author was a Member of the ISO 10009 Quality Tools, ISO 10014 Financial and Economic Benefits of ISO 9001, ISO 10017 Statistical Techniques. Currently on the ISO WG 29 ISO 9001 Revision

- The MMC PSPG uses Dr WE Deming’s PDSA “Learning Cycle” and supports DMAIC Six Sigma™, A3 Lean; PDCA Dr Shewhart & Dr Deming; 8D Aerospace and Defense; IDEA for Science; Breakthrough Dr Juran; Corrective Action ISO MS Standards